The ever-evolving world of technology continually introduces innovations, pushing boundaries and redefining what’s possible. One of the most influential advancements of recent times is the Internet of Things (IoT). Through IoT, our devices, machines, and systems communicate with each other, automating processes and enhancing user experience.

But, while connectivity is vital, ensuring electrical safety in this interconnected web is paramount. This blog post dives deep into how IoT has reshaped electrical safety, and where panel interface connectors come into play.

IoT: Delving Deeper into Unprecedented Connectivity

The marvel of the Internet of Things (IoT) lies in its capacity to unify a multitude of devices under a single communicative umbrella. No longer are we bound by the limitations of individualized, standalone devices. Instead, we’ve embarked on a journey where the smallest gadgets to the largest machines participate in a symphony of data exchange. It’s a world where your refrigerator isn’t just a storage space; it becomes an intelligent assistant, recommending culinary delights based on its contents. Similarly, in industries, IoT isn’t just about automation; it’s about utilizing real-time data to make production not just faster, but smarter, leaner, and more efficient.

Yet, amidst these revolutionary strides, an essential question emerges: With the surge in connected devices, how do we anchor our systems in safety? Indeed, the increasing complexity requires that our safety measures aren’t just adequate but are ahead of the curve. This foresight ensures that while we harness the full potential of IoT, we’re rooted in foundational safety principles, particularly with the integration of evolving devices like panel interface connectors.

Real-time Monitoring: Beyond the Surface of Contemporary Systems

While the primary allure of IoT revolves around connectivity, its value in safety systems, particularly in real-time monitoring, is groundbreaking. In previous models, monitoring was a reactive process—often we’d become aware of a malfunction only when a system failed or during scheduled maintenance. However, the present paints a drastically different picture. With IoT-driven systems, every second becomes an opportunity for monitoring. Such an environment offers distinct advantages:

- Instant Alerts: Anomalies don’t lurk in the shadows for long. The minute a discrepancy surfaces, whether it’s a voltage fluctuation or a temperature spike, the system is poised to notify the relevant stakeholders. This immediacy isn’t just about addressing the issue; it’s about potential disaster aversion.

- Shifting Paradigms: From Reactive to Proactive: Traditional monitoring awaited the onset of a problem. Modern IoT systems, however, champion a proactive stance. Technicians are now equipped with the insights to anticipate issues, transforming their roles from problem solvers to problem preventers.

- Optimized Efficiency: When a system is continually observed, it’s less prone to sudden breakdowns. This constant vigilance ensures that systems don’t just work, but they work at their pinnacle, harmonizing energy conservation with reduced strain on equipment.

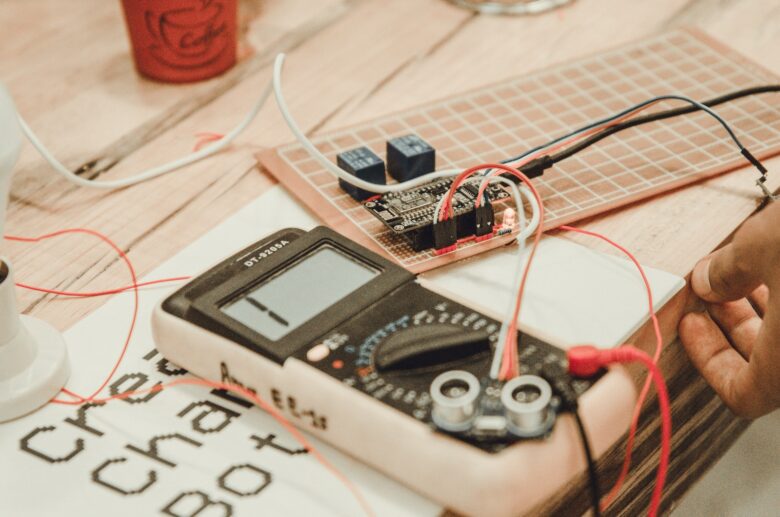

Central to this real-time monitoring are devices like panel interface connectors. More than mere components, they’re bridges—allowing technicians a glimpse into the system’s heart while ensuring this access doesn’t disrupt the system’s equilibrium.

Predictive Maintenance: The Crystal Ball of Modern Systems

If the present landscape of IoT is mesmerizing, its potential to foresee challenges is nothing short of magical. Through predictive maintenance, IoT transforms raw data into insightful forecasts, identifying potential challenges long before they morph into tangible problems. This forward-looking approach draws parallels with medical diagnostics, where early detection can be the line between a minor treatment and a major surgery. The merits of such predictive prowess include:

- Augmenting Equipment Longevity: When potential issues are recognized and rectified in their nascent stages, the overall strain on equipment diminishes, paving the way for extended operational lifespans.

- Minimizing Interruptions: In a business landscape where time equates to currency, predictive maintenance can preemptively identify maintenance windows, ensuring that work processes remain largely unaffected.

- Economic Prudence: In the long haul, early problem detection and rectification can translate to substantial financial savings, circumventing the hefty expenses that often accompany major repairs or replacements.

Panel interface connectors stand tall as sentinels in this predictive environment. They function as secure portals, enabling technicians to remotely access critical diagnostics, eliminating the need for intrusive or direct system interventions.

Remote Access and Safety: Crafting the Ideal Symbiosis

The realm of remote access, at first glance, might seem fraught with vulnerabilities. The idea of accessing systems, especially critical ones, from a distance could raise eyebrows regarding safety. Yet, in the IoT landscape, remote doesn’t translate to risky. In fact, devices like panel interface connectors have been pivotal in debunking this myth. Their integration into modern systems highlights:

- Strategic Isolation: Even as these connectors offer a window into the system, they’re adept at ensuring the main infrastructure remains untouched by potential electrical discrepancies that might arise during diagnostics or calibrations.

- Empowered Diagnostics: The emphasis isn’t just on remote access but on empowered access. Technicians, irrespective of their physical location, can delve deep into system analytics, ensuring timely interventions while sidestepping the risks of direct, manual system handling.

- Evolutionary Design Philosophy: The design framework of these connectors isn’t static. They’re continually evolving, reflecting the needs of an ever-growing IoT paradigm. Every iteration aims to offer more secure, efficient, and user-friendly access, attesting to their significance in the IoT safety matrix.

Safety in an IoT-driven Future

The realm of IoT is still expanding, and as it grows, the intricacies of electrical safety will evolve. As we transition from standalone systems to an interconnected web of devices, the dynamics of safeguarding these networks become paramount. What remains constant, however, is the unwavering commitment to protect both systems and their end-users from potential hazards. Devices and components, especially instrumental ones like panel interface connectors, will continue to play pivotal roles in melding the worlds of safety and connectivity. Their adaptability and evolving designs are testaments to their significance in this landscape.

Today, as we stand at this crossroads of rapid technological advancement and inherent challenges, the integration of IoT in electrical safety signifies more than just progress. It epitomizes a vision—of smart systems and safer environments. It’s not merely about streamlining operations or enhancing system efficiencies; it’s about pioneering a future where technology doesn’t just serve us but also vigilantly guards us. In this evolving narrative, the emphasis is clear: ensuring that as we stride toward a more connected tomorrow, every step is illuminated with safety and assurance.